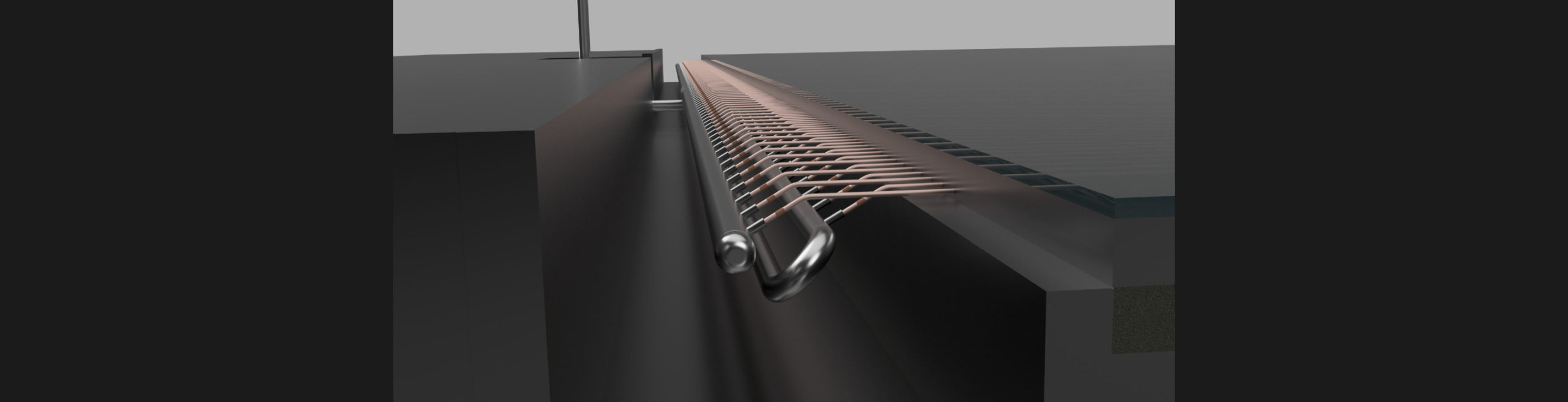

CO pump

CO pump is a flooded direct transcritical CO2 system available from 200 kW right through to 1 mW, making it suitable for flooded CO2 blast freezers, such as spiral and tunnel types, as well as a range of other applications such as direct transcritical CO2 ice rinks and many other high capacity process cooling applications.

-

CO pump

Standard Features

CO pump

Standard Features

- CO2 Liquid Temperature Span -50°C through to +2°C

- 60 Bar MWP Liquid Vessel

- Run and Standby Liquid CO2 Pumps

- isentra drum Oil System

- isentra Dynamic PHX Superheat Management

- Two Year Parts Warranty

- Aluminium Cladding To Insulation

- Integrated PLC Control

- Internet Connectivity

- Robust PFC, RHS & SHS Steel Frame Construction

- Lifting Eyes

- 3-Layer Cold Vessel Protection: Petrolatum Tape, Plastic Film, Class O Closed Cell Insulation

- Resilient Powder Coated Paint Finish - C3 Specification

-

CO pump

Available Options

CO pump

Available Options

- Full Range of Liquid Vessel Capacities

- Glycol Thermosiphon Evaporators For Secondary Cooling Loads

- Bespoke Frame Sizes

- Remote PRV Stations