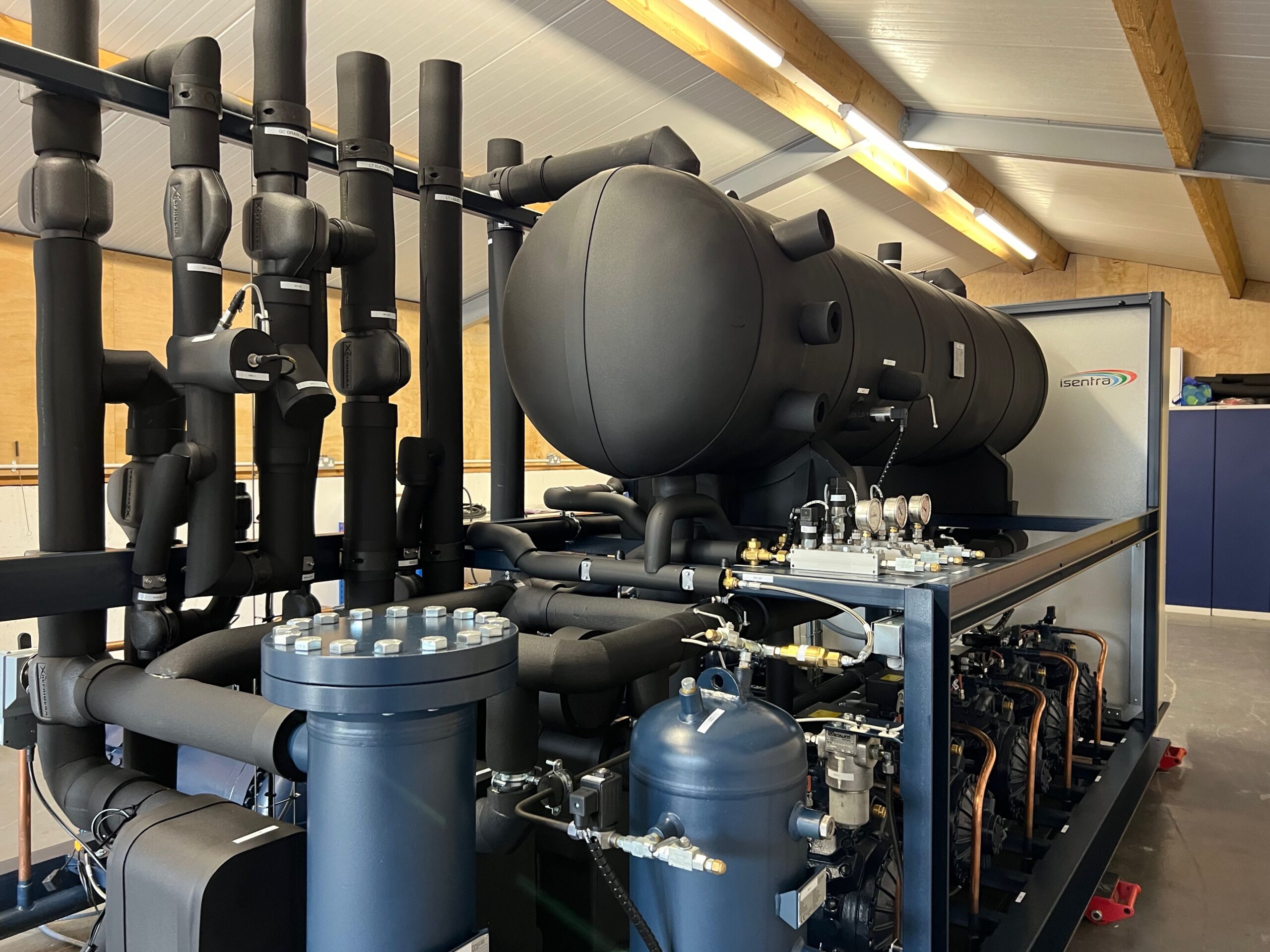

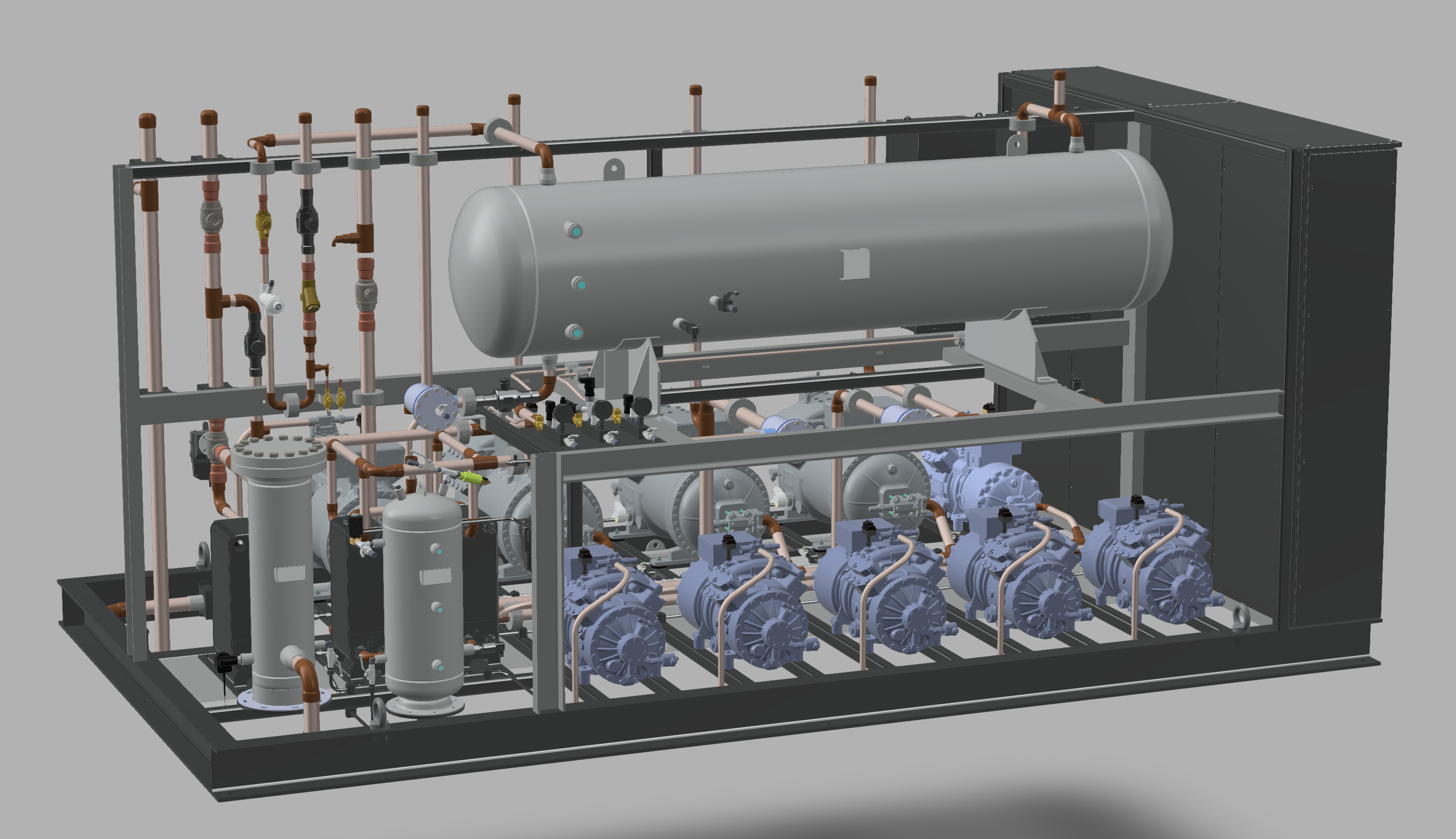

CO six

Industrial Transcritical CO2

The CO six range is built for industrial refrigeration, from -50°C blast freezers through to +12°C air conditioning applications, using six cylinder piston compressors to offer durable, high capacity cooling.

-

CO six

Standard Features

CO six

Standard Features

- 250 kW to 1.2 MW

- Multi Temperature Capability

- -50°C to +12°C Evaporating Temperature Range

- Comprehensive PHX Superheat Management

- Lifting Eyes

- Internet connectivity

- High Capacity Oil System

- Inverter Driven Lead Compressors

- 2 Year Parts Warranty

- Fully Interactive Control, Monitoring & Alarm System

- Power Consumption Monitoring

- Precision Gas Cooler & Receiver Pressure Control via Stepper Valve Technology

- Intelligent Oil Separator Control

- Individual Compressor Oil Level Management

- Fully Serviceable Instrument Manifolds

- Premium Quality Pressure Transducers

- Premium Quality Pressure Limiters for Control

- Visual Pressure Gauges

- Type Approved Pressure Cut-Outs

- Dual PRV Arrangements

- Selectable Liquid Receiver Size

- Serviceable Oil Reservoir

- Accessible High Pressure Coalescent Oil Separator

- 3-Point Oil Filtration: High Pressure Separator Outlet, Oil Res Outlet, Compressor Oil Solenoid

- High Stage Suction Filter Drier

- Liquid Line Filter

- Gas Cooler Return Filter

- Comprehensive Isolation & Service Access

- K65 Suction Header/s

- Steel Discharge Header/s

- K65 Stub Connections

- Sturdy PFC, RHS & SHS Steel Frame Construction

- Resilient Powder Coated Paint Finish - C3 Specification

- 3-Layer Cold Vessel Protection: Petrolatum Tape, Plastic Film, Class O Closed Cell Insulation

- Class O Cold Pipework Isolation

- High Quality Pipework & Component Bracketry

-

CO six

Available Options

CO six

Available Options

- Heat Recovery Options

- Total Heating Operation

- Hot Gas Defrost System

- Industrial CO2 Heat Pump Operation

- Compatible with CO pump - Flooded Transcritical CO2

- Compatible with CO chill - Transcritical Water Chiller

- Back-Up Control System

- Dual/Backup MPV

- Dual/Backup HPV

- Dual Inverter per Section

- Parallel Compression

- HP Ejector Technology

- Stainless Steel Stub Connections

- Liquid Line Filter Drier

- Anti-Vibration Floor Mounts

- Control Platform Manufacturer